Found the problem

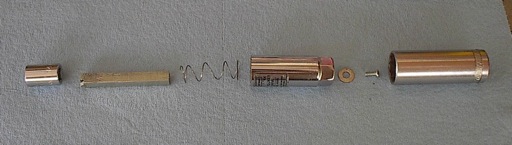

So, last update on the '66 Corsa was I had put a "basement" 110 in it that was said to be a good runner when pulled. On startup, it had enormous blowby out the vent tube, no apparent smoke out the tailpipe. My thought and the concensus on VV was that most likely a broken ring. Well, we were close, the #2 piston is eroded at the top of the cylinder all the way down to the top ring (click on the photo for a full size image):

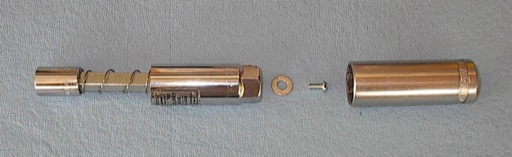

The head looks ok, with just a little bit of aluminum sprayed into the coubustion chamber:

I am replacing the cylinders and barrels, my concern is what caused this, I would guess that it was running lean at some point. I'm using a different set of carbs but the head will go back on. Anything else I should look at? Thanks for any suggestions.